Video

Codsiga

Qalabka lagu dabaqi karo ee Mashiinka Goynta Fiber Laser

Mashiinka goynta fiber laser gooyn karaa ahama, steel carbon, bir khafiif ah, birta alloy, birta galvanized, silicon steel, birta guga, sheet titanium, xaashi galvanized, sheet birta, xaashida inox, aluminium, naxaas, naxaas iyo xaashi kale biraha, biraha saxan, tuubo bir ah iyo tuubo, iwm.

Warshadaha lagu dabaqi karo Mashiinka Goynta Fiber Laser

Mashiinka goynta laser fiber waxaa loo isticmaali karaa warshado badan.Tusaale ahaan, qaybaha mishiinada, korontada, samaynta xaashida biraha, golaha korantada, qalabka jikada, guddi wiishka, qalabka hardware, xayndaabka biraha, waraaqaha calaamada xayeysiiska, nalalka iftiinka, farsamada biraha, qurxinta, dahabka, qalabka caafimaadka, qaybaha baabuurta iyo meelaha kale ee biraha goynta .

Tusaale

Habaynta

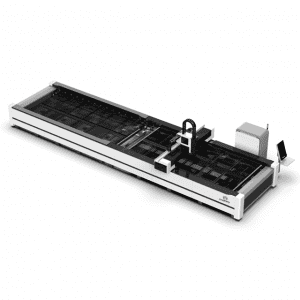

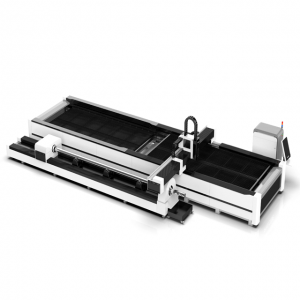

Labada Miisaska Sarrifka Degdegga ah

Jirka birta ah ee jaranjaradan ayaa lagu sameeyay daawaynta kulaylka 600°C, waxaana lagu qaboojiyey foornada gudaheeda 24 saacadood.Ka dib marka tan la dhammeeyo, waxaa lagu farsameeyaa iyadoo la isticmaalayo mishiinka wax-shiidka ee plano-ka waxaana lagu alxanayaa iyadoo la isticmaalayo kaarboon laba ogsaydh.Tani waxay hubinaysaa inay leedahay awood sare iyo nolol adeeg 20 sano ah.

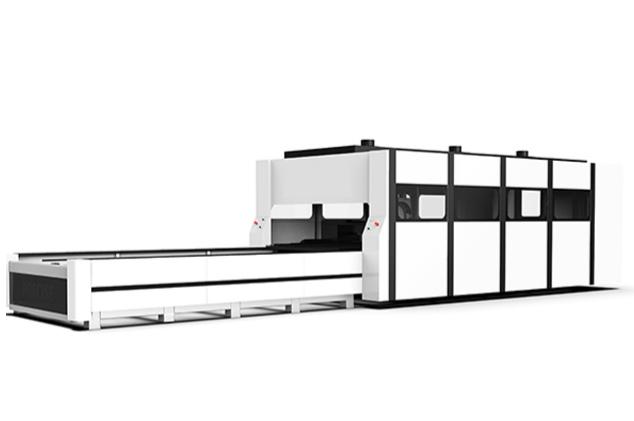

Heerka Badbaadada Sare

Dahaarka difaaca oo dhan ayaa go'doomiya shucaaca laysarka iyo wasakhowga, taasoo bixisa heer badbaado oo sarreeya.Qiiqa iyo boodhka la soo saaro inta lagu jiro goynta ayaa si toos ah loo ururin doonaa si loo hubiyo in goob nadiif ah lagu shaqeeyo, oo ku habboon heerka CE ee Yurub.Nidaamka la socodka smart wuxuu caawiyaa dhimista heerka shilalka.

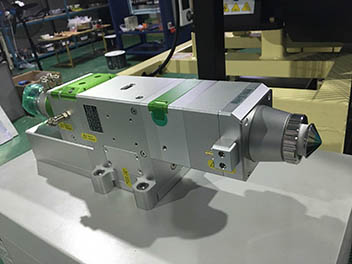

Switzerland Raytools Laser Head

Madaxa laser-ka ayaa lagu dabaqi karaa dhererka foorarka ee kala duwan, kaas oo lagu xakameynayo nidaamka xakamaynta qalabka mashiinka.Barta xudunta ayaa si toos ah loo hagaajin doonaa habka goynta si loo gaaro saamaynta goynta ugu fiican ee dhumucyada kala duwan ee birta.Kordhinta dhererka diiradda daloolinta, si gooni gooni ah u dejinaya dhererka xudunta daloolinta iyo goynta dhererka fog, waxay hagaajisaa saxnaanta goynta.

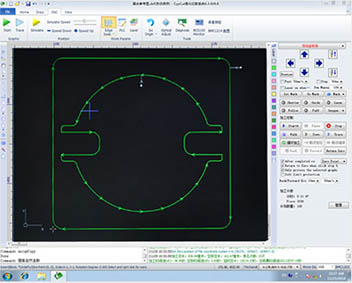

Nidaamka Xakamaynta CYPCUT

Nidaamka Xakamaynta CYPCUT ee mashiinka goynta laser-ka fiber-ka ayaa xaqiijin kara qaabeynta caqliga leh ee goynta garaafyada waxayna taageertaa soo dejinta sawirro badan, hagaajinta amarada goynta si toos ah, cidhifyada raadinta si caqli-gal ah iyo meeleyn toos ah.Nidaamka xakamaynta wuxuu qaataa barnaamijka macquulka ah ee ugu fiican iyo isdhexgalka software, wuxuu bixiyaa khibrad shaqo oo cajiib ah, si wax ku ool ah u wanaajinta isticmaalka biraha xaashida iyo yaraynta qashinka.Nidaamka hawlgalka fudud oo degdeg ah, tilmaamaha goynta hufan oo sax ah, si wax ku ool ah u wanaajiso khibradda isticmaale.

BCS100 Xakamaynta Dhererka Kartida

BCS100 kontoroolka dhererka capacitive (kadib loo tixraaco BCS100) Mashiinka goynta laysarka fiber-ka waa aalad kantaroolka waxqabadka sare leh kaas oo isticmaalay habka xakamaynta-loop-ka-xiran.BCS100 waxay sidoo kale bixisaa isgaarsiin u gaar ah Ethernet (TCP / IP Protocol), waxay si fudud u gaari kartaa hawlo badan oo leh software CypCut, sida si toos ah ula socoshada dhererka, daloolinta qaybsan, daloolinta horumarka, raadinta geesaha, boodada, dejinta aan loo baahnayn ee dhererka kor u qaadista madax goynta. Heerkeeda jawaab celinta ayaa sidoo kale si weyn loo hagaajiyay.Gaar ahaan gudahaDhinacyada kantaroolka servo, xawaarihiisa orodkiisa iyo saxnaantiisa waa inay si cad uga fiicnaadaan alaabada kale ee la midka ah, taasoo ay ugu wacan tahay xawaaraha iyo booska laba-laab-xidhan ee algorithm.Taageer alaarmiga marka aad garaacayso looxa iyo meel ka baxsan cidhifka.Taageer ogaanshaha cidhifka iyo kormeerka tooska ah.

Xuduudaha farsamada

| Qaabka Mashiinka | Taxanaha KP |

| Mawjada dhererka | 1070nm |

| Aagga Goynta | 3000*1500mm / 4000*2000mm / 6000*2000mm/ 6000*2500mm |

| Awoodda leysarka | 1000W / 1500W / 2000W / 3000W / 4000W / 6000W / 8000W / 12KW / 15KW / 20KW / 30KW |

| Saxnaanta meelaynta dhidibka X/Y | 0.03mm |

| Saxnimada Dib u Dhigista dhidibka X/Y | 0.02mm |

| Max.Dardargelinta | 1.5G |

| Max.xawaaraha isku xirka | 140m/daqiiqo |

Goynta xuduudaha

| Goynta Halbeegyada | 1000W | 1500W | 2000W | 3000W | 4000W | |

| Qalab | Dhumucda | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min |

| Birta Kaarboon ( Bir khafiif ah ) | 1 | 8.0--10 | 15--26 | 24--32 | 30--40 | 33--43 |

| 2 | 4.0--6.5 | 4.5--6.5 | 4.7--6.5 | 4.8--7.5 | 15--25 | |

| 3 | 2.4--3.0 | 2.6--4.0 | 3.0--4.8 | 3.3--5.0 | 7.0--12 | |

| 4 | 2.0--2.4 | 2.5--3.0 | 2.8--3.5 | 3.0--4.2 | 3.0--4.0 | |

| 5 | 1.5--2.0 | 2.0--2.5 | 2.2--3.0 | 2.6--3.5 | 2.7--3.6 | |

| 6 | 1.4--1.6 | 1.6--2.2 | 1.8--2.6 | 2.3--3.2 | 2.5--3.4 | |

| 8 | 0.8--1.2 | 1.0--1.4 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | |

| 10 | 0.6--1.0 | 0.8--1.1 | 1.1--1.3 | 1.2--2.0 | 1.5--2.4 | |

| 12 | 0.5--0.8 | 0.7--1.0 | 0.9--1.2 | 1.0--1.6 | 1.2--1.8 | |

| 14 | 0.5--0.7 | 0.8--1.0 | 0.9--1.4 | 0.9--1.2 | ||

| 16 | 0.6-0.8 | 0.7--1.0 | 0.8--1.0 | |||

| 18 | 0.5--0.7 | 0.6--0.8 | 0.6--0.9 | |||

| 20 | 0.5--0.8 | 0.5--0.8 | ||||

| 22 | 0.3--0.7 | 0.4--0.8 | ||||

| Birta aan daahin (Inox) | 1 | 18--25 | 20--27 | 24--50 | 30--35 | 32--45 |

| 2 | 5--7.5 | 8.0--12 | 9.0--15 | 13--21 | 16--28 | |

| 3 | 1.8--2.5 | 3.0--5.0 | 4.8--7.5 | 6.0--10 | 7.0--15 | |

| 4 | 1.2--1.3 | 1.5--2.4 | 3.2--4.5 | 4.0--6.0 | 5.0--8.0 | |

| 5 | 0.6--0.7 | 0.7--1.3 | 2.0-2.8 | 3.0--5.0 | 3.5--5.0 | |

| 6 | 0.7--1.0 | 1.2-2.0 | 2.0--4.0 | 2.5--4.5 | ||

| 8 | 0.7-1.0 | 1.5--2.0 | 1.2--2.0 | |||

| 10 | 0.6--0.8 | 0.8--1.2 | ||||

| 12 | 0.4--0.6 | 0.5--0.8 | ||||

| 14 | 0.4--0.6 | |||||

| Aluminium | 1 | 6.0--10 | 10--20 | 20--30 | 25--38 | 35--45 |

| 2 | 2.8--3.6 | 5.0--7.0 | 10--15 | 10--18 | 13--24 | |

| 3 | 0.7--1.5 | 2.0--4.0 | 5.0--7.0 | 6.5--8.0 | 7.0--13 | |

| 4 | 1.0--1.5 | 3.5--5.0 | 3.5--5.0 | 4.0--5.5 | ||

| 5 | 0.7--1.0 | 1.8--2.5 | 2.5--3.5 | 3.0--4.5 | ||

| 6 | 1.0--1.5 | 1.5--2.5 | 2.0--3.5 | |||

| 8 | 0.6--0.8 | 0.7--1.0 | 0.9--1.6 | |||

| 10 | 0.4--0.7 | 0.6--1.2 | ||||

| 12 | 0.3-0.45 | 0.4--0.6 | ||||

| 16 | 0.3--0.4 | |||||

| Naxaas | 1 | 6.0--10 | 8.0--13 | 12--18 | 20--35 | 25--35 |

| 2 | 2.8--3.6 | 3.0--4.5 | 6.0--8.5 | 6.0--10 | 8.0--12 | |

| 3 | 0.5--1.0 | 1.5--2.5 | 2.5--4.0 | 4.0--6.0 | 5.0--8.0 | |

| 4 | 1.0--1.6 | 1.5--2.0 | 3.0-5.0 | 3.2--5.5 | ||

| 5 | 0.5--0.7 | 0.9--1.2 | 1.5--2.0 | 2.0--3.0 | ||

| 6 | 0.4--0.9 | 1.0--1.8 | 1.4--2.0 | |||

| 8 | 0.5--0.7 | 0.7--1.2 | ||||

| 10 | 0.2--0.5 | |||||

-

Kaarboon-Aabaha Birta Fiber Laser Cutter oo leh ...

-

6 Axis 3D fiber laser goynta robot

-

4KW 6KW 8KW Birta CNC Fiber Laser Machi-goyn

-

Dhuumaha birta ee laba-isticmalan iyo saxan Fiber Laser cutt...

-

Tuubo Toos ah oo Bir ah iyo Dhuumaha Fiber Laser Cutti...

-

Fur Nooc Bir ah Sheet Fiber Laser Machine Goynta