Video

Codsiga

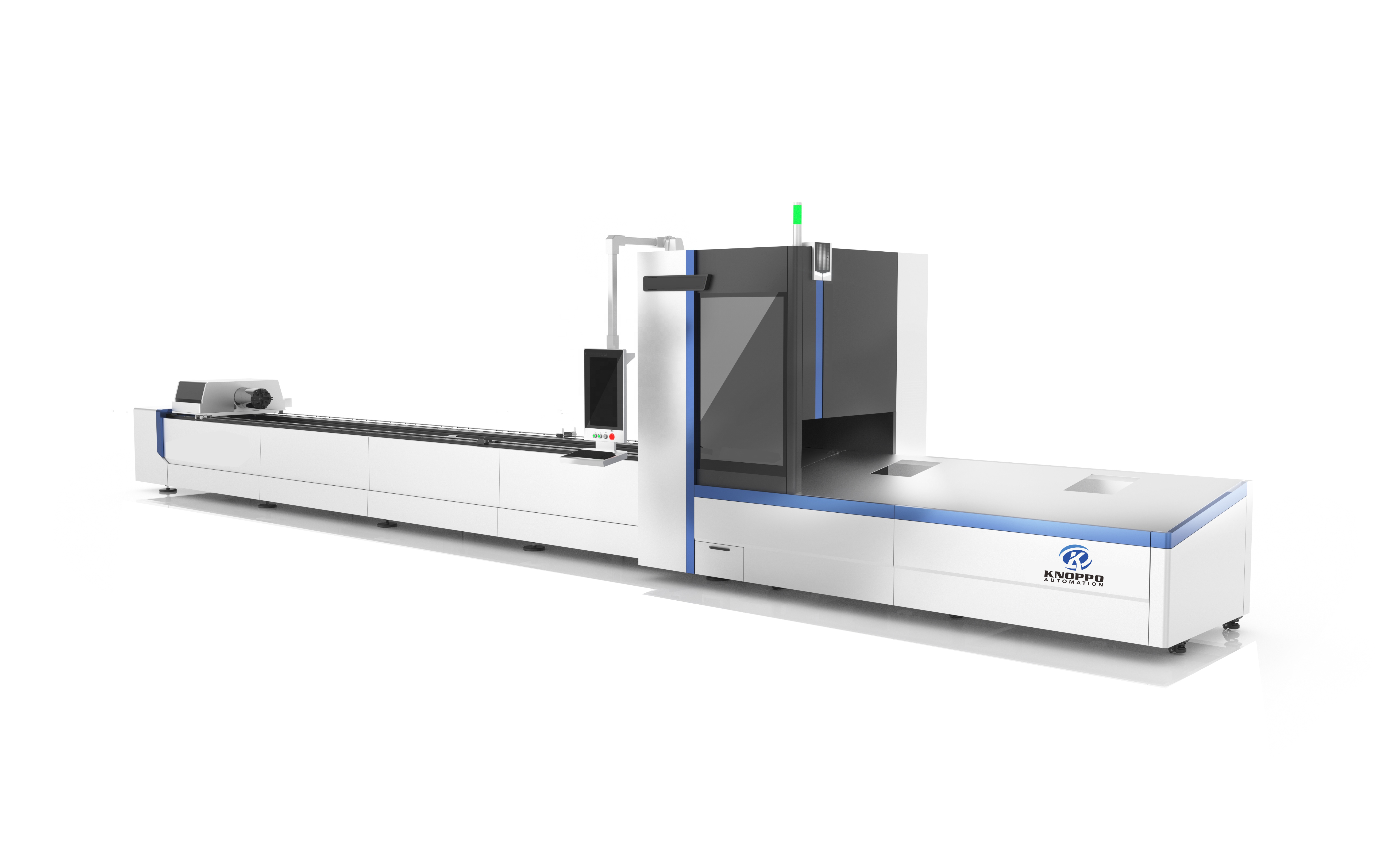

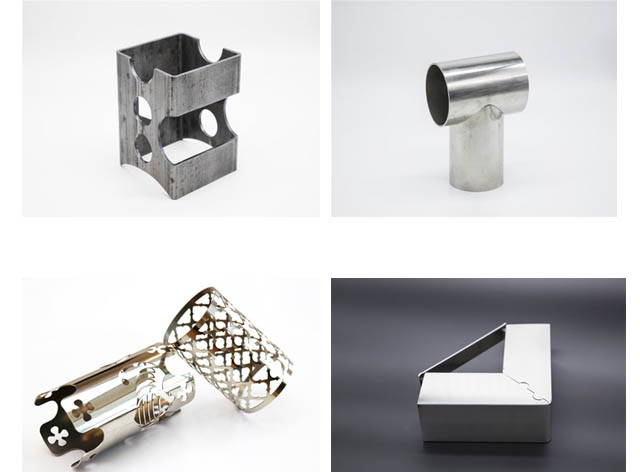

Qalabka lagu dabaqi karo ee Mashiinka Goynta Fiber Laser Tube

KT6 fiber laser tube jarida tube ahama, tube steel carbon, tube bir khafiif ah, tube galvanized, tube birta, tube inox, tube aluminium, tube naxaas ah iyo tuubo kale oo bir ah, biraha biraha.Qaabku wuxuu noqon karaa tuubo wareegsan, tuubo labajibbaaran, tuubo leydi ah iyo bir xagal iwm.

Warshadaha lagu dabaqi karo ee Mashiinka Goynta Fiber Laser Tube

Qaybaha mishiinada, korontada, samaynta biraha xaashida, golaha korantada, qalabka jikada, wiishka, agabka qalabka, xidhitaanka birta, waraaqaha calaamada xayaysiinta, nalalka iftiinka, farsamada birta, qurxinta, dahabka, qalabka caafimaadka, qaybaha baabuurta, alaabta guriga iyo meelaha kale ee birta lagu gooyo.

Tusaale

Habaynta

Quwad koronto oo toos ah

Si otomaatig ah u qaboojiyaha korantada, wadista mashiinka DC-ga.Matoorka xajinaya hadda waa xasaasi, la hagaajin karo oo deggan.Qiyaasta xajintu way ka sii ballaadhan tahay xoogga isku xidhka ayaa ka weyn.Tuubooyin aan burbursanayn, isku xidhid toos ah oo degdeg ah iyo tuubbada isku dhejinta, waxqabadkeedu aad buu u deggan yahay.Cabbirka chuck-ka ayaa ka yar, is-beddelka wareeggu waa hooseeyaa, waxqabadka firfircooni waa mid xooggan.Isku-dubarid koronto oo is-xakameysa, habka gudbinta qalabka, waxtarka gudbinta sare, nolosha shaqada ee dheer iyo kalsoonida shaqada sare.

Chuck Indheer garadnimada CNC Isku-dubarid, Xakamaynta Saxda ah ee Booska Isku-xidhka

CNC-ga caqliga leh ee is-xakameeya booska saxda ah ee saxda ah iyo kantaroolka qulqulka ayaa si xor ah u bedeli kara tuubada dhumucdeedu kala duwan tahay, waxay ka hortagtaa qaladka qanjaruufo iyo qallafsanaanta haynta tuubada dhuuban.

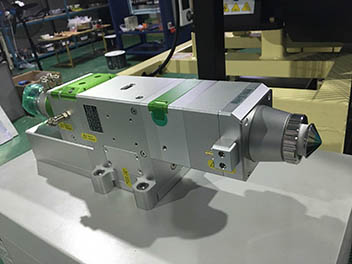

Switzerland Raytools Laser Head

Lagu dabaqi karo dhererka focal ee kala duwan, kuwaas oo ay gacanta ku hayaan nidaamka xakamaynta qalabka mashiinka.Kordhinta dhererka diiradda daloolinta, si gooni gooni ah u dejinaya dhererka xudunta daloolinta iyo goynta dhererka fog, waxay hagaajisaa saxnaanta goynta.NO.1 Astaanta aduunka.

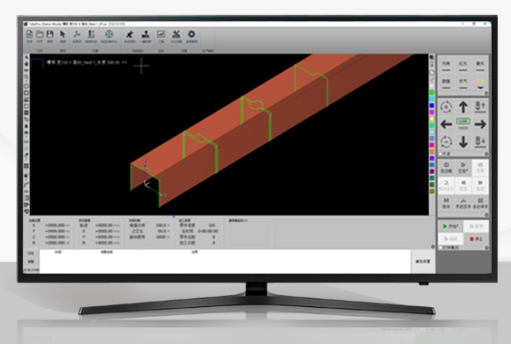

Nidaamka Xakamaynta CYPCUT

Nidaamka Xakamaynta CYPCUT ee mashiinka goynta tube laser waxay xaqiijin kartaa qaabeynta caqliga leh ee goynta sawirada waxayna taageertaa soo dejinta sawirro badan, hagaajinta amarada goynta si toos ah, cidhifyada raadinta si caqli-gal ah iyo meeleyn toos ah.Nidaamka xakamaynta wuxuu qaataa barnaamijka macquulka ah ee ugu fiican iyo isdhexgalka software, wuxuu bixiyaa khibrad shaqo oo cajiib ah, si wax ku ool ah u wanaajinta isticmaalka biraha xaashida iyo yaraynta qashinka.Nidaamka hawlgalka fudud oo degdeg ah, tilmaamaha goynta hufan oo sax ah, si wax ku ool ah u wanaajiso khibradda isticmaale.

Qaboojiyaha Biyaha

Si otomaatig ah u xakamee heerkulka madaxa laysarka iyo isha laysarka.

Xuduudaha farsamada

| Qaabka | KT6 |

| Mawjada dhererka | 1070nm |

| Dhexroor goynta ugu badan | 350mm |

| Dhererka Goynta Tube | 6m / 9m / 12m |

| Awoodda leysarka | 1000W / 1500W / 2000W / 3000W / 4000W |

| Saxnaanta meelaynta dhidibka X/Y | 0.03mm |

| Saxnimada Dib u Dhigista dhidibka X/Y | 0.02mm |

| Max.Dardargelinta | 1.5G |

| Max.xawaaraha isku xirka | 140m/daqiiqo |

Goynta xuduudaha

| Goynta Halbeegyada | 1000W | 1500W | 2000W | 3000W | 4000W | |

| Qalab | Dhumucda | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min | xawaaraha m/min |

| Birta kaarboon | 1 | 8.0--10 | 15--26 | 24--32 | 30--40 | 33--43 |

| 2 | 4.0--6.5 | 4.5--6.5 | 4.7--6.5 | 4.8--7.5 | 15--25 | |

| 3 | 2.4--3.0 | 2.6--4.0 | 3.0--4.8 | 3.3--5.0 | 7.0--12 | |

| 4 | 2.0--2.4 | 2.5--3.0 | 2.8--3.5 | 3.0--4.2 | 3.0--4.0 | |

| 5 | 1.5--2.0 | 2.0--2.5 | 2.2--3.0 | 2.6--3.5 | 2.7--3.6 | |

| 6 | 1.4--1.6 | 1.6--2.2 | 1.8--2.6 | 2.3--3.2 | 2.5--3.4 | |

| 8 | 0.8--1.2 | 1.0--1.4 | 1.2--1.8 | 1.8--2.6 | 2.0--3.0 | |

| 10 | 0.6--1.0 | 0.8--1.1 | 1.1--1.3 | 1.2--2.0 | 1.5--2.4 | |

| 12 | 0.5--0.8 | 0.7--1.0 | 0.9--1.2 | 1.0--1.6 | 1.2--1.8 | |

| 14 |

| 0.5--0.7 | 0.8--1.0 | 0.9--1.4 | 0.9--1.2 | |

| 16 |

|

| 0.6-0.8 | 0.7--1.0 | 0.8--1.0 | |

| 18 |

|

| 0.5--0.7 | 0.6--0.8 | 0.6--0.9 | |

| 20 |

|

|

| 0.5--0.8 | 0.5--0.8 | |

| 22 |

|

|

| 0.3--0.7 | 0.4--0.8 | |

| Bir daxal laheyn | 1 | 18--25 | 20--27 | 24--50 | 30--35 | 32--45 |

| 2 | 5--7.5 | 8.0--12 | 9.0--15 | 13--21 | 16--28 | |

| 3 | 1.8--2.5 | 3.0--5.0 | 4.8--7.5 | 6.0--10 | 7.0--15 | |

| 4 | 1.2--1.3 | 1.5--2.4 | 3.2--4.5 | 4.0--6.0 | 5.0--8.0 | |

| 5 | 0.6--0.7 | 0.7--1.3 | 2.0-2.8 | 3.0--5.0 | 3.5--5.0 | |

| 6 |

| 0.7--1.0 | 1.2-2.0 | 2.0--4.0 | 2.5--4.5 | |

| 8 |

|

| 0.7-1.0 | 1.5--2.0 | 1.2--2.0 | |

| 10 |

|

|

| 0.6--0.8 | 0.8--1.2 | |

| 12 |

|

|

| 0.4--0.6 | 0.5--0.8 | |

| 14 |

|

|

|

| 0.4--0.6 | |

| Aluminium | 1 | 6.0--10 | 10--20 | 20--30 | 25--38 | 35--45 |

| 2 | 2.8--3.6 | 5.0--7.0 | 10--15 | 10--18 | 13--24 | |

| 3 | 0.7--1.5 | 2.0--4.0 | 5.0--7.0 | 6.5--8.0 | 7.0--13 | |

| 4 |

| 1.0--1.5 | 3.5--5.0 | 3.5--5.0 | 4.0--5.5 | |

| 5 |

| 0.7--1.0 | 1.8--2.5 | 2.5--3.5 | 3.0--4.5 | |

| 6 |

|

| 1.0--1.5 | 1.5--2.5 | 2.0--3.5 | |

| 8 |

|

| 0.6--0.8 | 0.7--1.0 | 0.9--1.6 | |

| 10 |

|

|

| 0.4--0.7 | 0.6--1.2 | |

| 12 |

|

|

| 0.3-0.45 | 0.4--0.6 | |

| 16 |

|

|

|

| 0.3--0.4 | |

| Naxaas | 1 | 6.0--10 | 8.0--13 | 12--18 | 20--35 | 25--35 |

| 2 | 2.8--3.6 | 3.0--4.5 | 6.0--8.5 | 6.0--10 | 8.0--12 | |

| 3 | 0.5--1.0 | 1.5--2.5 | 2.5--4.0 | 4.0--6.0 | 5.0--8.0 | |

| 4 |

| 1.0--1.6 | 1.5--2.0 | 3.0-5.0 | 3.2--5.5 | |

| 5 |

| 0.5--0.7 | 0.9--1.2 | 1.5--2.0 | 2.0--3.0 | |

| 6 |

|

| 0.4--0.9 | 1.0--1.8 | 1.4--2.0 | |

| 8 |

|

|

| 0.5--0.7 | 0.7--1.2 | |

| 10 |

|

|

|

| 0.2--0.5 | |